Construction Case Study: Electro-tech CP

Electro-tech CP Ltd, a leading Cathodic Protection company, has worked with MHA for more than 6 years.

Cathodic Protection involves preventing electrolytic corrosion of iron and steel by controlling the electrical potential difference between the metal and its surroundings. The process is extended to protection of any steel framed structure that is encased in concrete (bridges, multi storey buildings) by controlling both the electrical potential of the steel, and the concrete chemistry. Electro-Tech CP has installations across Europe, the Middle East and USA

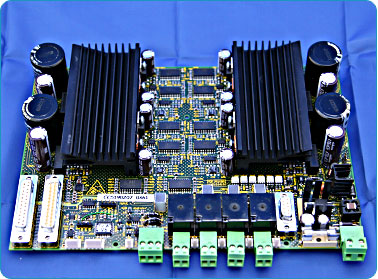

During our association we have developed a complete range of products involving power supplies, control, data logging, communications and more… including a "ruggedised" controller as replacement for the industrial PC formerly used to run the installed systems.

The nature of this application requires product which will operate unsupervised for up to 25 years under widely varying environmental conditions. Systems are built from combinations of single-channel and four-channel DC constant current/constant voltage sources, with variable scheduled data logging. Our DC sources achieve high efficiency and compact size, in comparison with alternative products. The data which can be recorded include applied voltage and current, reference electrode potentials, depolarisation test data, and Linear Polarisation Resistance. Monitoring may be continuous and live, or up to 10 years' data recorded in non-volatile memory for later retrieval.

MHA has all product manufactured and tested locally in the UK, supplying Electro-tech CP with cards to "plug in" at system level integration.